Power your digitalization process

Are you getting the most out of the opportunities offered by the latest technologies?

Digitization in business operations plays a fundamental role in their competitiveness. In maintenance operations, digitization affects the reliability and availability of assets, the effectiveness of the resources used or the quality of the operations - the effectiveness - At DOT we have carried out a study on the management of computer-assisted maintenance (CMAO ) whose results were obtained through a survey carried out on the occasion of the presence of DOT Consulting in the 7th Spanish and 21st Ibero-American Maintenance Congress held last May 2023 in the town of Tarragona.

Computer-Aided Maintenance Management (CAMM)

A relevant fact obtained from the study is the fact that there are still 30% of companies that do not have a software that helps them manage their maintenance.

It is clear that companies with a GMAO cover their maintenance needs to a greater extent (80% coverage) compared to those without (60% coverage). However, companies using a GMAO fail to take advantage of the full potential, as they only use 65% of the software's functionality.

A major obstacle to achieving this optimal use of the GMAO functionalities is the lack of team training and an incomplete implementation of the system. 30% of companies have not yet implemented a GMAO, and many times the cause of this is resistance to change.

Detection support (intervention notices)

An aspect rarely used in maintenance management is the detection of duplicate notices, which makes it difficult to effectively plan and schedule work and also to coordinate with production areas. Data science makes it possible to identify these duplications and assess their importance. On the other hand, this causes inefficiencies in the use of resources due to the significant time spent to eliminate duplications.

These systems require an appropriate parameterization of the warnings in order to provide great advantages in maintenance management, such as the monitoring of equipment and the assessment of the criticality of the warnings and the risks of failures.

The main obstacle for companies lies in the diversity of perceptions between departments, since few have automatic systems for assessing criticality, causing discrepancies in the scheduling of work orders. The second obstacle is the quality of the information, often affected by inadequate parameterizations and less rigorous data.

Mobility in execution

There are tools whose use should be more frequent, since they have great potential to generate improvements in efficiency. A clear example is mobility in execution, more than 60% of companies have this, however, not all manage to take full advantage of it. Most of the time it is due to resistance to change on the part of intervention teams.

Taking pictures, on the other hand, is also a highly valued tool in mobility management, as it facilitates the identification of the causes of equipment errors and, also, to determine which are the most effective maintenance strategies. However, few companies benefit from it, these do not reach 30%, and even fewer (<10%) have it integrated into the system.

Support for intervention through data science

It is surprising that less than 15% of companies have up-to-date plans and diagrams of their facilities and equipment. Having immediate and up-to-date information on the current situation of the equipment speeds up the diagnosis of possible failures and allows interventions to be more effective. In addition, the plans and diagrams make it possible to analyze the behavior of the equipment in different operational situations and, also, the causes of breakdowns.

Augmented reality is a resource that makes use of data science. Not everyone has this tool, as it requires a lot of resources. In fact, less than 3% of respondents claim to use it. This technology of the future allows "on-site" access to equipment information, speeds up error diagnoses and makes interventions more effective.

Maintenance strategies

With regard to the maintenance strategies, it is necessary to emphasize the importance of an adequate parameterization of the system, as well as the possibility of having a volume of historical data of high quality, thus constituting the basis for the application of the data science, in particular artificial intelligence, for fault prescription.

Several companies are implementing solutions that make use of Natural Language Processing (PLN). These solutions, by means of the historical data of interventions and the operating parameters of the equipment, have the ability to indicate to the technicians which type of intervention is the most appropriate.

Having a breakdown prescription method is crucial to avoid costly breakdowns. One way to carry out this action is through systematic breakdown analysis, as 80% of the surveyed companies already do. This analysis allows us to know which type of maintenance is most suitable for the different teams. There are three types: first, the reactive, which consists of a repair in the event of a breakdown; secondly, the preventive, which is applied based on time or use; and last but not least, predictive, this is based on condition monitoring or data analysis.

Integration with other systems and equipment

Less than 30% of the companies have fully or partially included in their GMAO the integration of work permits. Having it improves the efficiency, safety and traceability of maintenance activities that require special permits, it also improves maintenance management and contributes to a safer work environment.

Another method to consider is system integration, such as materials management, which optimizes inventory, reduces costs and improves spare parts management. Regarding information systems, these facilitate the coordination of teams and departments (internal or external) involved in the execution and management of maintenance.

Positively, 80% of the companies surveyed state that internal departments share information through information systems and GMAO. However, only 20% ensure that the information systems are connected to their own.

This integration also benefits companies that perform maintenance for third parties, improving communication, visibility and the service provided.

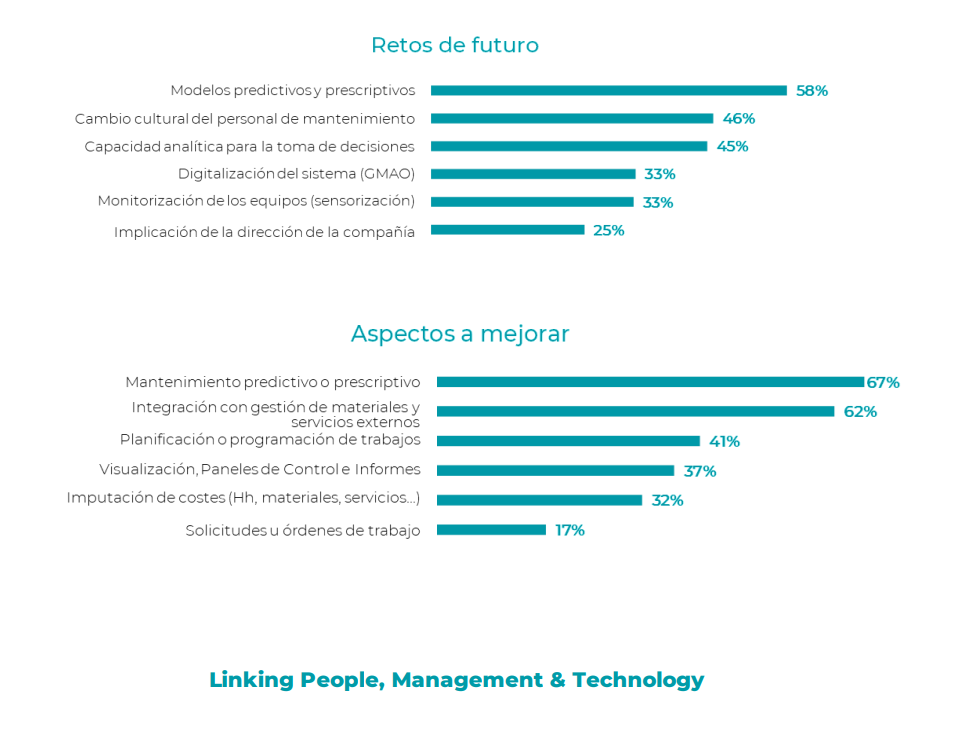

What does the future offer us?

Companies consider that their degree of digitization is between 60% and 70% of the current potential, in fact, the companies with the highest degree of digitization consider that they are still far from optimal digitization. This is in constant evolution, and leading companies understand the need to constantly adapt to remain competitive.

DOT Consulting has extensive experience in improving the management and digitization of maintenance in companies from various sectors.

DOT Consulting is not affiliated with any manufacturer or distributor of maintenance management software. This independence allows us to have the freedom to evaluate the different options that exist in the market and offer our customers the best solution according to their needs.

If you would like more information or deepen the opportunities for improvement that you consider your maintenance department has, contact aclaudio@dotconsulting.com, partner in charge of the DOT Consulting maintenance area.